The Definitive Guide to premade food packaging machines

The Definitive Guide to premade food packaging machines

Blog Article

Sauce manufacturers need to have to take care of the integrity and freshness of their merchandise while making certain an efficient generation. To realize this, sauce packaging machines are used to fill and pack sauce solutions.

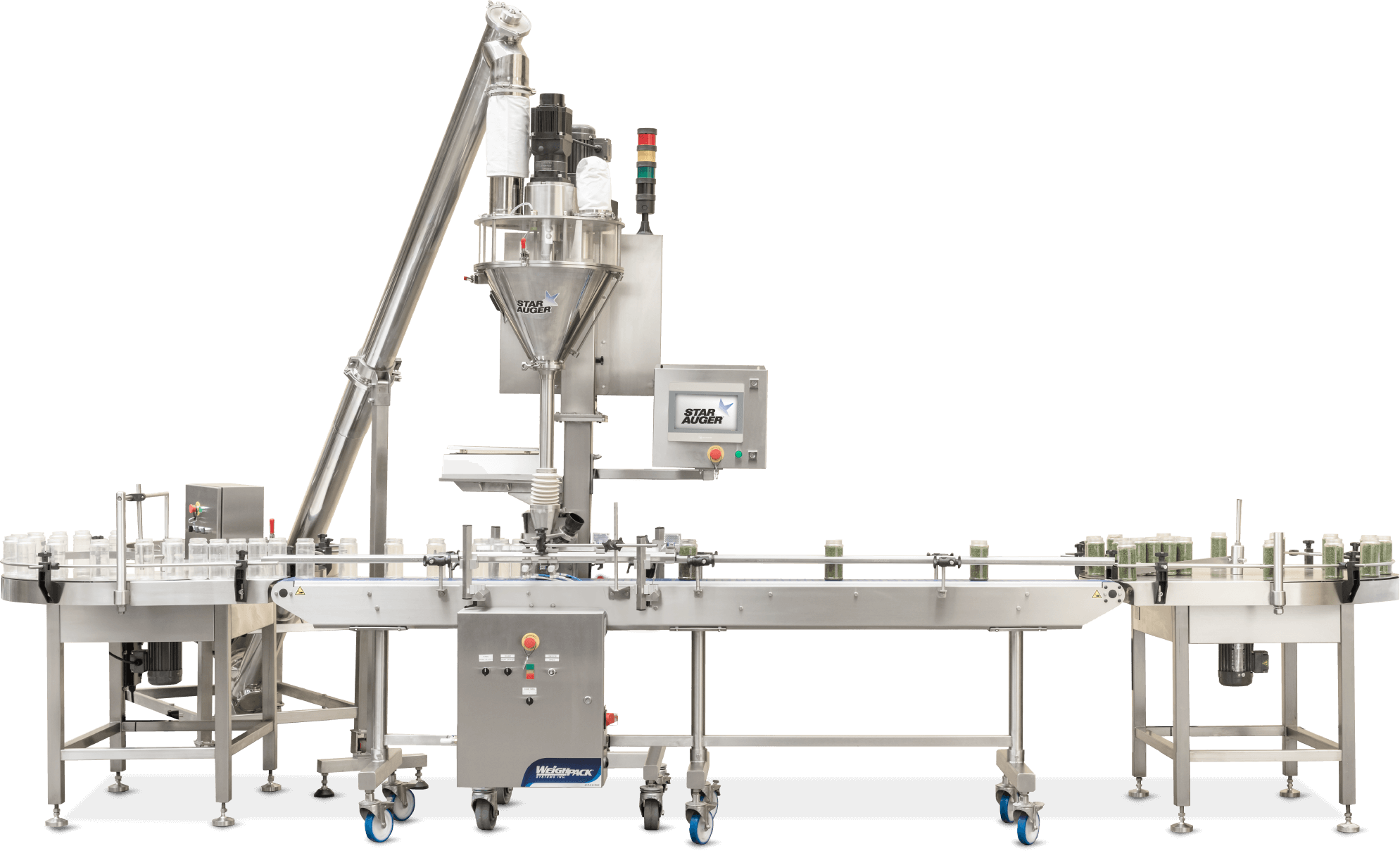

Pharmaceutical engineering has released many different turnkey options for powder packaging. For apparent knowing, We've labeled them down below:

It has large flexity by combining with several weigher and conveyor to packing diverse granule product, We're going to suggest most suitable for you.

To operate the rice packaging machine, you typically really need to follow the Recommendations about the operation panel or contact monitor, which include location the packaging specifications, altering the packaging pace, checking the operation position, etc. Make sure you consult with the machine’s guide for specific operation ways.

Rice packing machines normally include adjustable bag holders and equipment that may be adapted to distinct bag measurements and rice net weights by adjusting the system or changing the holder with an appropriate dimensions as liquid packaging machines required.

We will change how packaging cycles respond to good quality or throughput goals. Modular patterns help it become easy to switch formats with none downtime.

These higher-efficiency machines remove the necessity for pre-manufactured baggage through the use of laminated roll stock film to create a big number of flat pouch types and minimize product cost drastically.

R&D Office is chargeable for developing and researching machines to meet more consumer's needs

It was specifically formulated For warm pot seasoning, that is thick and sticky with various granule in it, ordinary sauce filling machine isn't match for it.

We have now liquid packaging machines an expert workforce, everyone seems to be supplying Skilled support to our customer in their responsibility portion, allyour needs is often reponsed immediately.

Sauce can filling machines is usually customized to fill and pack various kinds of sauce, unique containers, and sauce quantities.

The sauce bottle labeling machines can improve the performance and precision of labeling sauce solutions, that makes it uncomplicated for corporations to simplify their functions and Raise creation costs.

Enclosed mechanisms and explosion-resistant models support to minimize the risks of combustible elements.

Adopting vacuum packing might also contribute to environmental sustainability. Through the use of recyclable or eco-welcoming packaging possibilities, businesses can minimize plastic squander and their environmental footprint.